According to the WHO (World Health Organization), a staggering 15% of the world’s pharmaceuticals are not legitimate. When you stop to think about the implications of such a statistic, the effects of it truly hit home.

Now, more than ever, we need to have trust in the medications that we take and to have opportunists potentially erode the trust in the life-saving medications that your companies provide is abhorrent. So what can you do?

In order to counteract such a potentially dangerous issue, there are now coding measures that aim to fight black market medicine and the clear health hazard it presents.

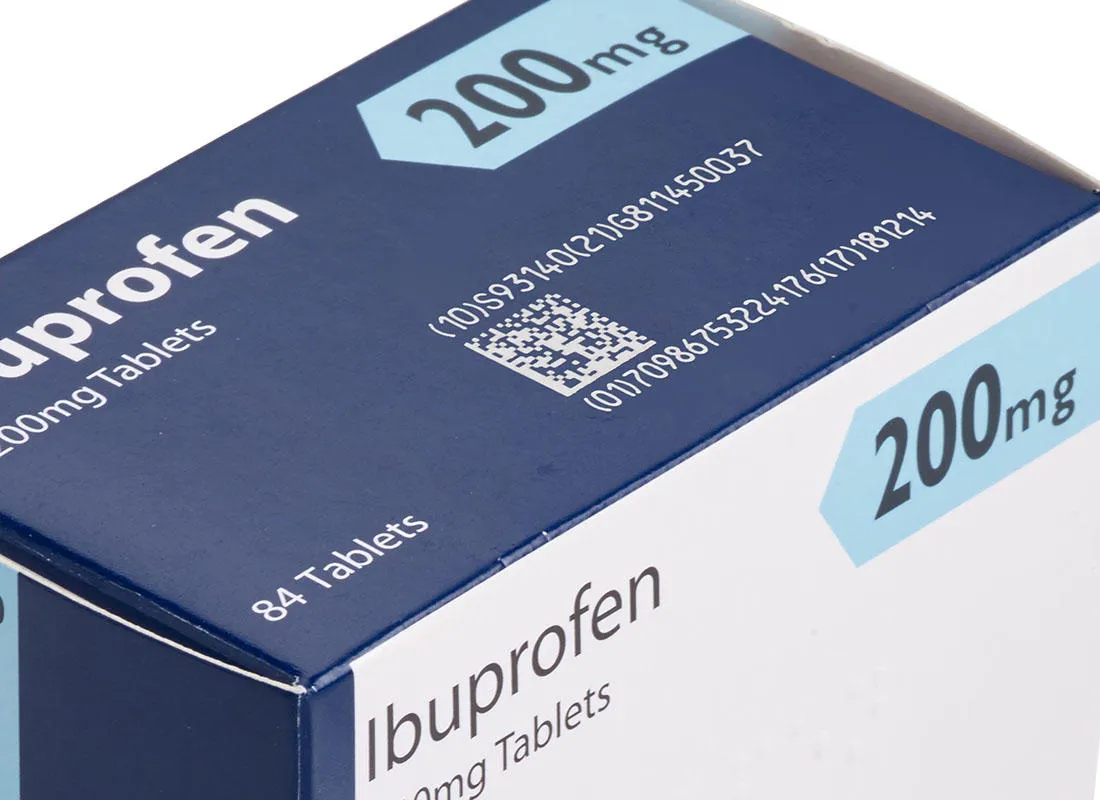

Now, all medicine cartons must contain a unique data matrix code (which must remain legible) and all products’ supply chain should be able to be easily traced back down to the manufacturer. That presents a significant logistical challenge - especially when the speed of packaging and coding is crucial to bottom lines - especially after 2020.

So how can it be done?

High quality, compliant coding at speed? Step forward Domino’s Pharma Laser.

Domino's bespoke CO2 Pharma Laser has been specifically developed as a coding machine for the exacting legislative requirements of the pharmaceutical industry. With the D-Series CO2 Laser, even thin, low-cost carton board is able to be marked with industry-compliant results, lending the manufacturer a huge advantage over competitors as well as the black market.

Domino's Pharma Laser was made for catering to different customers, different production lines and different substrates, setting it apart from other laser marking equipment on the market today.

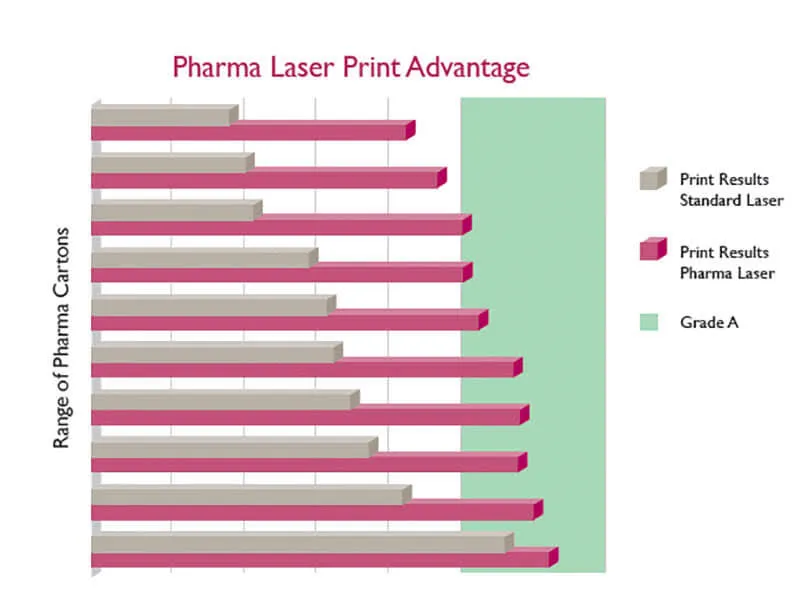

Efficiency? Domino knows nothing but creating the most efficient solutions - all while maintaining the industrial-level reliability of our laser markers that we are known for. We engineered the our lasers with the high-stress demands of the fast turnover of the medicine industry in mind. As a result, the Pharma Laser’s special properties means it can run coding at higher speeds without compromising code quality and legibility.

In addition, given the coding speed of our CO2 lasers, production line speed can be bumped up over 20%, meaning significant cost savings in production.

Plus, if your Pharmaceutical factory is running several products at fast turnaround, of course, you’re going to want a coding and marking system that works to your tight timescale, while also giving you the peace of mind that you’re adhering to legislature at every level of coding.

Different countries, different rules...

Of course, different countries abide by different code formats. Domino's CO2-based Pharma Laser is equipped to meet those varying requirements.

Unique item identification across a diverse range of formats is easy to arrange and extremely quick and easy to implement thanks to our QuickDesign label design software. Plus, as you know, the requirements are ever-changing.We've made the software easy-to-use as any other paint program on your computer, so you can change code imagery on the fly from a centralized location so if there are any changes in requirements (as is often the case) you will be ready for them in very little time.

You can easily place codes that change with each product, place logos, QR codes and several other options with our knowledge that we've gained from several other Pharmaceutical manufacturers just like you. For machine readable and human readable codes required for legislation, the Pharma Laser achieves a ‘Grade A’ when verified against ISO 15415.

Don’t just take our word for it...

In the past few years, the Pharmaceutical industry has never faced such a tough legislative challenge. Of course, no industry has faced a logistical challenge like we've just faced.

As a result of this combination of unique factors, packaging with item-level serialization is a serious test for any pharma manufacturer seeking to stay legally compliant but commercially and operationally successful. Plus, you've just faced on of the toughest logistical challenges in the modern era and managed to adapt your way through it. How do you continue to adapt? Domino can help.

It’s a coding conundrum to which Domino has the capability and expertise to help guide you through. Read more on the unique benefits of our D-Series CO2 laser marking machine and its effect on carton coding here. Or, you can also get in touch to find out how our unrivaled Laser portfolio could benefit your business.