In my last blog, Traceable Codes on Film, I shared the evolution of coding onto flexible films, and the introduction of lasers as a option from the traditional coding methods. This blog addresses which lasers work and why, from a more technical perspective. As there are a wide variety of films, it makes sense that there would need to be a variety of lasers to code these films. So let's dive right in to it.

Historically, most film coding had been done with hot wax, thermal transfer or CO2 lasers. However, laser coding was only feasible with a small subset of films which responded well to the CO2 energy.

Let's get technical for a second. Queue the CO2 laser talk.

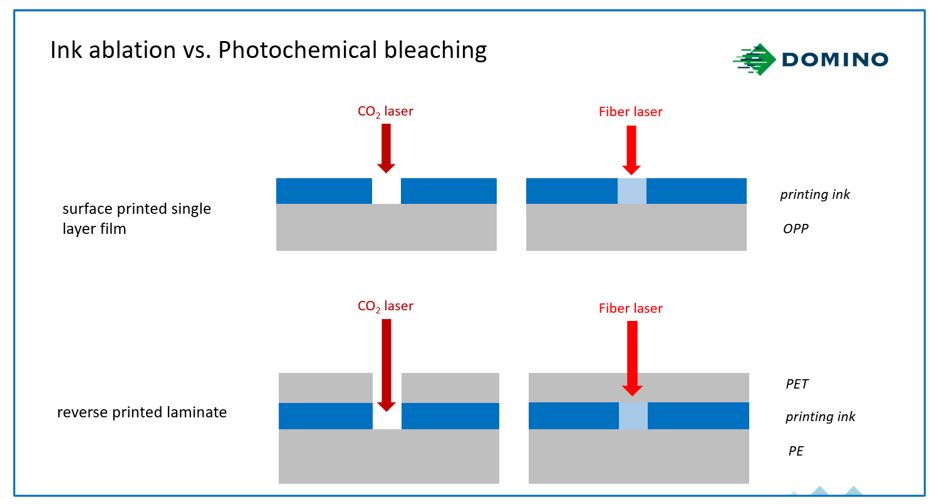

To simplify how laser works, the laser beam contacts the material, and its energy creates a reaction on the surface that leaves a permanent mark. The speed, power, and focus of the laser beam on the substrate will lead to different laser processes. CO2 lasers etch in the 10-micron wavelength range. This wavelength is in the mid-Infrared region and the energy from a CO2 Laser is more “heat” than light. Coding with CO2 lasers is a thermal process, where the film is coded by elevating the temperature in the code area, resulting in Ink ablation. CO2 laser coding is referred to as “Hot Coding” as a result.

CO2 laser coding removes material to create a code. As such, special care should be used to not compromise the barrier properties of the film.

CO2 laser coding works best with:

CO2 laser coding is dependent on good energy absorption by the substrate. If the substrate absorption is poor, then the code quality will be poor.

There are 3 different CO2 laser wavelengths -10.6, 10.2 & 9.3 microns. The coding performance of these different wavelengths is dependent on the substrate material. Selection of the most compatible wavelength is important to avoid any blistering effect

For example, our blue 9.3-micron wavelength will be much more effective on a PET layer. Our red 10.2-micron wavelength will be much more effective on a Polypropylene layer.

Fiber Lasers are changing the game.

Fiber lasers lase in the 1-micron wavelength range. This wavelength is in the near-Infrared region which is much closer to visible light. Coding with Fiber lasers is a photochemical process where the film is coded by breaking a molecular bond to create color change. It is not a thermal process and Fiber Laser coding is referred to as “Cold Coding”.

Fiber laser coding creates a color change but typically does not remove material to create a code. It can work on all materials, as long as the color itself can be photochemically changed.

Fiber lasers can code these new materials in three different ways:

- Photochemical color changed (colors need to be specified)

- De-metallization (preferably on the fin seal)

- Color change on base substrate (with proper film material)

Fiber lasers have the ability to shape the laser pulses which can be used to optimize codes and eliminate any thermal effects (blistering, perforation).

Fiber laser coding is proving applicable on a larger percentage of flexible films and is the fasted growing option for laser coding films.

The next step: Where do you start when considering a Laser?

There are so many elements to consider, but the first step is to align with a supplier who has the understanding and expertise from a Material Science perspective to work with you to help you explore your options.

The first step that Domino will always recommend is to connect with us to have your films analyzed in the North American sample lab to determine the most suitable laser coding approach. The Domino sample tab team will develop a thorough sample report complete with science insights to then make the best decision.

I invite you to connect with me on LinkedIn and reach out to me with any of your questions you might have. I also encourage you to review other content we have developed for you related to the laser journey.